Patent Number: №7585134 B2

Application Number: 10\854565

Foreign Application Priority Data: 02 June 2003г.

Registration Date: 08 September 2009г.

Assignee: Yurkevich Engineering Bureau Ltd.

Application Number: 10\854565

Foreign Application Priority Data: 02 June 2003г.

Registration Date: 08 September 2009г.

Assignee: Yurkevich Engineering Bureau Ltd.

Reinforced-concrete column in the soil pit and method of its construction

Abstract

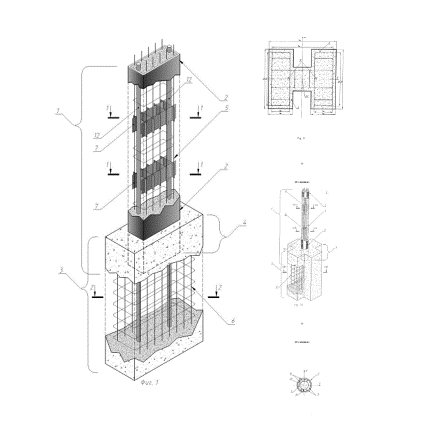

A reinforced-concrete column contains reinforcing cage and inserts made monolithic with concrete mix and comprises the upper bearing and lower foundation parts. The method of construction of the column includes operations of manufacture of the column reinforcing cage with inserts, placement of concrete in the non-removable casing in the project position in single- or multi-slit pit with the column making monolithic. The column reinforcing cage is loaded vertically into the pit, centered vertically, and the upper part is fixed from horizontal displacements, the lower foundation part of the column and the inner part of the non-removable casing with the closed-type casing in the upper bearing part of the column are made monolithic with concrete from down to top. After making monolithic, the soil base is widened and cemented via the process pipeline placed inside the reinforcing cage; the space between the non-removable casing and the pit walls in the upper bearing part is filled with granular material. 4 Claims, 24 Drawing Sheets.

Field of the Application

The invention relates to the art of construction, especially in straitened conditions, in particular, to the elements and methods of monolithic construction of elements of buildings and structures, and namely, bearing reinforced-concrete elements.

A reinforced-concrete column contains reinforcing cage and inserts made monolithic with concrete mix and comprises the upper bearing and lower foundation parts. The method of construction of the column includes operations of manufacture of the column reinforcing cage with inserts, placement of concrete in the non-removable casing in the project position in single- or multi-slit pit with the column making monolithic. The column reinforcing cage is loaded vertically into the pit, centered vertically, and the upper part is fixed from horizontal displacements, the lower foundation part of the column and the inner part of the non-removable casing with the closed-type casing in the upper bearing part of the column are made monolithic with concrete from down to top. After making monolithic, the soil base is widened and cemented via the process pipeline placed inside the reinforcing cage; the space between the non-removable casing and the pit walls in the upper bearing part is filled with granular material. 4 Claims, 24 Drawing Sheets.

Field of the Application

The invention relates to the art of construction, especially in straitened conditions, in particular, to the elements and methods of monolithic construction of elements of buildings and structures, and namely, bearing reinforced-concrete elements.

Summary of the invention

It is an object of the present invention to provide a reinforced concrete column in the soil pit.

Another object of the present invention is to provide new method of construction of said reinforced concrete column in the soil pit The technical aim of the invention and technical result—raising accuracy over vertical when installing bearing foundation elements and elements carrying the load of construction of the building or structure and providing possibility of constructing the building, structure simultaneously upwards and downwards below the zero mark.

According to the present invention, there is provided a reinforced-concrete column, comprises reinforcing cage made monolithic with the concrete mix and inserts, consisting of the upper bearing and lower foundation parts, in contrast to the known column, is made in the single-or multi-slit soil pit. In this case, the upper part of reinforcing cage is arranged in non-removable casing with the closed-type contour, projection of geometric center of cross-section of which is combined with projection of geometric center of cross-section of the lower part of reinforcing cage, and the sizes of the branches of the lower part of the reinforcing cage along axis Y are taken with the proviso that:

It is an object of the present invention to provide a reinforced concrete column in the soil pit.

Another object of the present invention is to provide new method of construction of said reinforced concrete column in the soil pit The technical aim of the invention and technical result—raising accuracy over vertical when installing bearing foundation elements and elements carrying the load of construction of the building or structure and providing possibility of constructing the building, structure simultaneously upwards and downwards below the zero mark.

According to the present invention, there is provided a reinforced-concrete column, comprises reinforcing cage made monolithic with the concrete mix and inserts, consisting of the upper bearing and lower foundation parts, in contrast to the known column, is made in the single-or multi-slit soil pit. In this case, the upper part of reinforcing cage is arranged in non-removable casing with the closed-type contour, projection of geometric center of cross-section of which is combined with projection of geometric center of cross-section of the lower part of reinforcing cage, and the sizes of the branches of the lower part of the reinforcing cage along axis Y are taken with the proviso that:

AKi<ABi by value Ωy=2(εy+αy+βy), by where Y—axis passing through geometric center of cross-section of the lower part of the cage; AKi—basic sizes of branches of the lower part of the column cage along axis Y; ABi—basic sizes of pit slits corresponding to them along axis Y; K—index of the size related to the cage; B—index of the size related to slit-pit; i—size index; εy—component of eccentricity along axis Y of projection of geometric center of one-piece column reinforcing cage relative to projection of its center of masses in the plane of its top; αy—maximum deviation of the pit from vertical along axis Y; βy—deviation of geometric center of cross-section of the pit in the plane along axis Y in the plane of the column top, the sizes of branches of the lower part of reinforcing cage along axis X are taken with the proviso that:

BKi<BBi by value Ωx=2(εx+αx+βx), where X—axis passing through geometric center of cross-section of the lower part of the cage, perpendicular to axis Y; BKi—basic sizes of branches of the lower part of the column cage along axis X; BBi—basic sizes of the pit slits along axis X; εx—component of eccentricity along axis X of projection of geometric center of the column one-piece reinforcing cage relative to projection of its center of masses in the plane of its top; αx—maximum deviation of the pit from vertical along axis X: βx—deviation of geometric center of cross-section of the pit in the plane along axis X in the plane of the column top, and the inserts are arranged in the upper bearing part of the column at the levels of the marks of the foundation slab and the marks of the floor slabs and made in the form of closed-type contours with stiffening ribs.

The column is made in non-removable casing in the borehole with reinforcing cage equivalent maximum outer diameter DK<DC by value it ΩΓ=2(εΓ+αΓ+βΓ), where Dc=AB=BB—diameter of the borehole; εΓ=√(εx2+εy2)—total eccentricity of projection of geometric axis relative to projection of axis of center of masses of the column in the plane of the column top; αΓ=√(αx2+αy2)—total deviation of axis of the borehole from vertical; βΓ=√(βx2+βy2)—total deviation of axis of the borehole in the plane; non-removable casing is made from the pipe of round, rectangular or other arbitrary cross-section with closed-type contour symmetrical with respect to axes X, Y; the lower part of the column is provided with the bottom hole chamber and fixing rods.

The reinforcing cage part arranged in the lower foundation part of the column is connected “lap joint” with the reinforcing cage part arranged in the upper bearing part with attachment of elements of the reinforcing cage.

In the slit pits the sizes of the reinforcing cage part arranged in the upper bearing part of the column are equal or less than inner sizes of non-removable casing with the closed-type contour, basic sizes along axes X, Y of the branches of the reinforcing cage lower part arranged in the lower foundation part of the column are equal or more than basic outer sizes of the non-removable casing.

In the borehole pits the equivalent outer diameter of the reinforcing cage part arranged in the upper bearing part of the column is equal or less than the inner diameter of the non-removable casing; the equivalent inner diameter of the reinforcing cage part arranged in the lower foundation part of the column is equal or more than the outer diameter of the non-removable casing.

According to the present invention, there is provided a method of construction of the reinforced-concrete column in the soil pit includes operations of manufacture of the column reinforcing cage with inserts, placement of concrete in the non-removable casing in the project position in single-or multi-slit pit with provision of making the column monolithic.

The column is made in non-removable casing in the borehole with reinforcing cage equivalent maximum outer diameter DK<DC by value it ΩΓ=2(εΓ+αΓ+βΓ), where Dc=AB=BB—diameter of the borehole; εΓ=√(εx2+εy2)—total eccentricity of projection of geometric axis relative to projection of axis of center of masses of the column in the plane of the column top; αΓ=√(αx2+αy2)—total deviation of axis of the borehole from vertical; βΓ=√(βx2+βy2)—total deviation of axis of the borehole in the plane; non-removable casing is made from the pipe of round, rectangular or other arbitrary cross-section with closed-type contour symmetrical with respect to axes X, Y; the lower part of the column is provided with the bottom hole chamber and fixing rods.

The reinforcing cage part arranged in the lower foundation part of the column is connected “lap joint” with the reinforcing cage part arranged in the upper bearing part with attachment of elements of the reinforcing cage.

In the slit pits the sizes of the reinforcing cage part arranged in the upper bearing part of the column are equal or less than inner sizes of non-removable casing with the closed-type contour, basic sizes along axes X, Y of the branches of the reinforcing cage lower part arranged in the lower foundation part of the column are equal or more than basic outer sizes of the non-removable casing.

In the borehole pits the equivalent outer diameter of the reinforcing cage part arranged in the upper bearing part of the column is equal or less than the inner diameter of the non-removable casing; the equivalent inner diameter of the reinforcing cage part arranged in the lower foundation part of the column is equal or more than the outer diameter of the non-removable casing.

According to the present invention, there is provided a method of construction of the reinforced-concrete column in the soil pit includes operations of manufacture of the column reinforcing cage with inserts, placement of concrete in the non-removable casing in the project position in single-or multi-slit pit with provision of making the column monolithic.

When constructing the column in single-or multi-slit pit, the column is made from upper bearing and lower foundation parts; in this case, the pit in soil is made with sizes along axis Y taken with the proviso that ABi>AKi+2(εy+αyβy) and along axis X with sizes taken with the proviso that BBi>BKi+2(εx+αx+βx), where Y—axis passing through geometric center of cross-section of the lower part of the cage; X—axis passing through geometric center of cross-section of the lower part of the cage, perpendicular to axis Y; AKi—basic sizes of branches of the lower part of the column cage along axis Y; BKi—basic sizes of branches of the lower part of the column cage along axis X; ABi—basic sizes of the pit slit along, axis Y corresponding to the branches; BBi—basic sizes of the pit slits along axis X; K—index of the size related to the cage; B—index of the size related to slit-pit; i—size index; εy and εx—components of eccentricity along axes Y and X, respectively, of projection of geometric center of one-piece reinforcing cage of the column respective to projection of its center of masses in the plane of its top; αy and αx—maximum deviations of the pit from vertical along axes Y and X, respectively; βy and βx—deviations of geometric center of cross-section of the pit in the plane along axes Y and X, respectively, in the plane of the column top. The column reinforcing cage is installed vertically into the pit with gap from its bottom, vertically centered with compensation for eccentricity and the upper part is fixed from horizontal displacements, the lower foundation part of the column and the internal part of non-removable casing with the closed-type contour in the upper bearing part of the column are made monolithic from down to top.

Concrete in the non-removable casing in the project position is placed in the borehole with provision of making it monolithic; in this case, the borehole is drilled with diameter Dc=AB=BB≧DK=AK=BK+2(εΓ+αΓ+βΓ) where DK—maximum equivalent outer diameter of the column reinforcing cage: εΓ=√(εx2+εy2)—total eccentricity of projection of geometric axis in regard with projection of the axis of center of masses of the column in the plane of the column top; αΓ=√(αx2+αy2)—total deviation of axis of the borehole from vertical; βΓ=√(βx2+βy2)—total deviation of axis of the borehole in the plane; the column reinforcing cage is vertically installed into the borehole with the gap from the borehole bottom by value P≧0.1 Dc, the upper part is vertically centered with compensation for eccentricity and fixed from horizontal displacements, is vertically lowered on the base of the borehole with fixation of the lower part with fixing plates, the lower foundation part of the column and internal part of non-removable casing of the upper bearing part of the column are made monolithic with concrete from down to top.

The soil base is widened and cemented after making monolithic via the process pipeline placed inside of the reinforcing cage; the space between non-removable casing and the walls of the pit are filled in the upper bearing part with granular material.

Concrete in the non-removable casing in the project position is placed in the borehole with provision of making it monolithic; in this case, the borehole is drilled with diameter Dc=AB=BB≧DK=AK=BK+2(εΓ+αΓ+βΓ) where DK—maximum equivalent outer diameter of the column reinforcing cage: εΓ=√(εx2+εy2)—total eccentricity of projection of geometric axis in regard with projection of the axis of center of masses of the column in the plane of the column top; αΓ=√(αx2+αy2)—total deviation of axis of the borehole from vertical; βΓ=√(βx2+βy2)—total deviation of axis of the borehole in the plane; the column reinforcing cage is vertically installed into the borehole with the gap from the borehole bottom by value P≧0.1 Dc, the upper part is vertically centered with compensation for eccentricity and fixed from horizontal displacements, is vertically lowered on the base of the borehole with fixation of the lower part with fixing plates, the lower foundation part of the column and internal part of non-removable casing of the upper bearing part of the column are made monolithic with concrete from down to top.

The soil base is widened and cemented after making monolithic via the process pipeline placed inside of the reinforcing cage; the space between non-removable casing and the walls of the pit are filled in the upper bearing part with granular material.